Chapter 18.08

AMENDMENTS TO CHAPTER 23, WOOD, OF THE CALIFORNIA BUILDING CODE

Sections:

18.08.005 Chapter 23 Is Amended.

18.08.010 Section 2304.10.2 Is Amended.

18.08.011 Section 2304.10.3.1 Is Added.

18.08.020 Section 2304.10.8 Is Amended.

18.08.030 Section 2304.10.9 Is Added.

18.08.040 Section 2304.12.2.8 Is Amended.

18.08.050 Section 2305.1.3 Is Added.

18.08.060 Section 2306.2 Is Amended.

18.08.070 Tables 2306.2(3), 2306.2(4), and 2306.2(5) Are Added.

18.08.080 Section 2306.3 Is Amended.

18.08.090 Section 2307.2 Is Added.

18.08.100 Table 2306.3(4) Is Added.

18.08.110 Table 2308.6.1 Is Amended.

18.08.120 Section 2308.6.5 Is Amended.

18.08.130 Section 2308.6.8.1 Is Amended.

18.08.140 Section 2308.6.9 Is Amended.

18.08.005 Chapter 23 Is Amended.

The following sections of Chapter 23 of the California Building Code, as adopted by Chapter 18.01 hereof, are added, deleted, or amended as follows. (Ord. 22-10 § 2, 12/13/22)

18.08.010 Section 2304.10.2 Is Amended.

Section 2304.10.2 is amended to read as follows:

2304.10.2 Fastener requirements. Connections for wood members shall be designed in accordance with the appropriate methodology in Section 2302.1. The number and size of fasteners connecting wood members shall not be less than that set forth in Table 2304.10.2. Staple fasteners in Table 2304.10.2 shall not be used to resist or transfer seismic forces in structures assigned to Seismic Design Category D, E or F.

Exception: Staples may be used to resist or transfer seismic forces when the allowable shear values are substantiated by cyclic testing and approved by the Building Official.

(Ord. 22-10 § 2, 12/13/22)

18.08.011 Section 2304.10.3.1 Is Added.

Section 2304.10.3.1 is added to read as follows:

2304.10.3.1 Quality of Nails. Mechanically driven nails used in wood structural panel shear walls shall meet the same dimensions as that required for hand-driven nails, including diameter, minimum length and minimum head diameter. Clipped head or box nails are not permitted in new construction. The allowable design value for clipped head nails in existing construction may be taken at no more than the nail-head-area ratio of that of the same size hand-driven nails.

(Ord. 22-10 § 2, 12/13/22)

18.08.020 Section 2304.10.8 Is Amended.

Section 2304.10.8 is amended to read as follows:

2304.10.8 Framing requirements. Wood columns and posts shall be framed to provide full end bearing. Alternatively, column-and-post end connections shall be designed to resist the full compressive loads, neglecting end-bearing capacity. Column-and-post end connections shall be fastened to resist lateral and net induced uplift forces. The minimum lateral design force for column and post end connections shall be 2% of the total axial compressive force acting on the column or post, but shall not be less than the force determined by analysis. The minimum lateral design force shall be assumed to act in any direction.

(Ord. 22-10 § 2, 12/13/22)

18.08.030 Section 2304.10.9 Is Added.

Section 2304.10.9 is added to read as follows:

2304.10.9 Nails, staples, or spikes in withdrawal. Nails, staples, or spikes shall not be used in withdrawal to resist the loads prescribed by this code.

Exceptions:

1. Fasteners connecting finish materials weighing 10 psf or less.

2. Fasteners connecting sheathing may be used to resist wind uplift loads.

3. Fasteners connecting roofing or cladding, when specifically approved by this code or by an approved listing or testing authority.

4. Fasteners connecting mechanical or electrical components weighing 20 lb or less, or in the case of a distributed system, 5 lb/ft or less.

(Ord. 22-10 § 2, 12/13/22)

18.08.040 Section 2304.12.2.8 Is Amended.

Section 2304.12.2.8 is amended to read as follows:

2304.12.2.8 Wood used in retaining walls and cribs. Wood installed in retaining or crib walls shall be preservative treated in accordance with AWPA U1 for soil and fresh water use. Wood shall not be used in retaining or crib walls for structures assigned to Seismic Design Category D, E, or F.

(Ord. 22-10 § 2, 12/13/22)

18.08.050 Section 2305.1.3 Is Added.

Section 2305.1.3 is added to read as follows:

2305.1.3 Lateral Design Standard. The American Wood Council’s (AWC) design standard Special Design Provisions for Wind and Seismic (SDPWS) may also be referred to as Special Provisions for the Design of Wind and Seismic (SPDWS).

(Ord. 22-10 § 2, 12/13/22)

18.08.060 Section 2306.2 Is Amended.

Section 2306.2 is amended to read as follows:

2306.2 Wood-frame diaphragms. Wood-frame diaphragms shall be designed and constructed in accordance with AWC SDPWS. Where panels are fastened to framing members with staples, requirements and limitations of AWC SDPWS shall be met and the allowable shear values set forth in Table 2306.2(1) or 2306.2(2) shall only be permitted for structures assigned to Seismic Design Category A, B, or C.

Exception: Allowable shear values where panels are fastened to framing members with staples may be used if such values are substantiated by cyclic testing and approved by the Building Official.

The allowable shear values in Tables 2306.2(1) and 2306.2(2) are permitted to be increased 40 percent for wind design.

Wood structural panel diaphragms used to resist seismic forces in structures assigned to Seismic Design Category D, E or F shall be applied directly to the framing members.

Exception: Wood structural panel diaphragms are permitted to be fastened over solid lumber planking or laminated decking, provided the panel joints and lumber planking or laminated decking joints do not coincide.

(Ord. 22-10 § 2, 12/13/22)

18.08.070 Tables 2306.2(3), 2306.2(4), and 2306.2(5) Are Added.

Tables 2306.2(3), 2306.2(4), and 2306.2(5) are added as follows:

|

Sheathing Grade |

Common Nail Size |

Minimum Fastener Penetration in Framing (in.) |

Minimum Nominal Panel Thickness (in.) |

Minimum Nominal Width of Nailed Face at Adjoining Panel Edges and Boundaries (in.) |

SEISMIC |

WIND |

||

|---|---|---|---|---|---|---|---|---|

|

6 in. Nail Spacing at diaphragm boundaries and supported panel edges |

6 in. Nail Spacing at diaphragm boundaries and supported panel edges |

|||||||

|

Case 1 |

Cases 2,3,4,5,6 |

Case 1 |

Cases 2,3,4,5,6 |

|||||

|

Structural I |

8d |

1-3/8 |

3/8 |

2 3 |

240 265 |

180 200 |

335 370 |

252 280 |

|

10d |

1-1/2 |

15/32 |

2 3 |

285 320 |

215 240 |

400 447 |

300 335 |

|

|

Sheathing and Single-Floor (DOC PS1 and PS2) |

6d |

1-1/4 |

3/8 |

2 3 |

165 185 |

125 140 |

230 260 |

175 195 |

|

8d |

1-3/8 |

3/8 |

2 3 |

215 240 |

160 180 |

300 335 |

225 252 |

|

|

7/16 |

2 3 |

230 255 |

170 190 |

322 357 |

237 265 |

|||

|

15/32 |

2 3 |

240 265 |

180 200 |

335 370 |

252 280 |

|||

|

10d |

1-1/2 |

15/32 |

2 3 |

255 290 |

190 215 |

357 405 |

265 300 |

|

|

19/32 |

2 3 |

285 320 |

215 240 |

400 447 |

300 335 |

|||

a. See AWC SDPWS for the following: For general construction requirements see 4.2.7. For specific requirements see 4.2.8.1 for wood structural panel diaphragms. See Appendix A for common nail dimensions.

b. For species and grades of framing other than Douglas-Fir-Larch or Southern Pine, reduced nominal unit shear capacities shall be determined by multiplying the tabulated nominal unit shear capacity by the Specific Gravity Adjustment Factor = [1-(0.5-G)], where G = Specific Gravity of the framing lumber from the NDS (Table 12.3.3A). The Specific Gravity Adjustment Factor shall not be greater than 1.

c. See AWC SDPWS Table 4.2C for Case definitions.

d. See AWC SDPWS Table 4.2C for the apparent shear stiffness values (Ga).

e. Tabulated nominal unit shear capacities are applicable for carbon steel smooth shank nails of the specified type and size.

|

Sheathing Grade |

Common Nail Size |

Minimum Nail Bearing Length in Framing Member or Blocking (in.) |

Minimum Nominal Panel Thickness (in.) |

Minimum Nominal Width of Nailed Face at Adjoining Panel Edges and Boundaries (in.) |

SEISMIC |

WIND |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Nail Spacing (in.) at diaphragm boundaries (all cases), at continuous panel edges parallel to load (Cases 3 & 4), and at all panel edges (Cases 5 & 6) |

Nail Spacing (in.) at diaphragm boundaries (all cases), at continuous panel edges parallel to load (Cases 3 & 4), and at all panel edges (Cases 5 & 6) |

|||||||||||

|

6 |

4 |

2-1/2 |

2 |

6 |

4 |

2-1/2 |

2 |

|||||

|

Nail Spacing (in.) at other panel edges (Cases 1, 2, 3, & 4) |

Nail Spacing (in.) at other panel edges (Cases 1, 2, 3, & 4) |

|||||||||||

|

6 |

6 |

4 |

3 |

6 |

6 |

4 |

3 |

|||||

|

Structural I |

8d |

1-3/8 |

3/8 |

2 3 |

270 300 |

360 400 |

530 600 |

600 675 |

377 420 |

505 560 |

742 840 |

840 945 |

|

10d |

1-1/2 |

15/32 |

2 3 |

320 360 |

425 480 |

640 720 |

730 820 |

447 505 |

595 672 |

895 1007 |

1022 1147 |

|

|

Sheathing and Single-Floor (DOC PS1 and PS2) |

6d |

1-1/4 |

3/8 |

2 3 |

185 210 |

250 280 |

375 420 |

420 475 |

260 295 |

350 392 |

525 587 |

587 665 |

|

8d |

1-3/8 |

3/8 |

2 3 |

240 270 |

320 360 |

480 540 |

545 610 |

335 377 |

447 505 |

672 755 |

762 855 |

|

|

7/16 |

2 3 |

255 285 |

340 380 |

505 570 |

575 645 |

357 400 |

475 532 |

707 797 |

805 902 |

|||

|

15/32 |

2 3 |

270 300 |

360 400 |

530 600 |

600 675 |

377 420 |

505 560 |

742 840 |

840 945 |

|||

|

10d |

1-1/2 |

15/32 |

2 3 |

290 325 |

385 430 |

575 650 |

655 735 |

405 455 |

540 602 |

805 910 |

917 1030 |

|

|

19/32 |

2 3 |

320 360 |

425 480 |

640 720 |

730 820 |

447 505 |

595 672 |

895 1007 |

1022 1147 |

|||

a. See AWC SDPWS for the following: For general construction requirements see 4.2.7. For specific requirements see 4.2.8.1 for wood structural panel diaphragms. See Appendix A for common nail dimensions.

b. For species and grades of framing other than Douglas-Fir-Larch or Southern Pine, reduced nominal unit shear capacities shall be determined by multiplying the tabulated nominal unit shear capacity by the Specific Gravity Adjustment Factor = [1-(0.5-G)], where G = Specific Gravity of the framing lumber from the NDS (Table 12.3.3A). The Specific Gravity Adjustment Factor shall not be greater than 1.

c. See AWC SDPWS Table 4.2A for Case definitions.

d. See AWC SDPWS Table 4.2A for the apparent shear stiffness values (Ga).

e. Tabulated nominal unit shear capacities are applicable for carbon steel smooth shank nails of the specified type and size.

|

Sheathing Grade |

Common Nail Size |

Minimum Nail Bearing Length in Framing Member or Blocking (in.) |

Minimum Nominal Panel Thickness (in.) |

Minimum Nominal Width of Nailed Face at Adjoining Panel Edges and Boundaries (in.) |

Lines of Nails |

SEISMIC |

WIND |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Nail Spacing (in.) at diaphragm boundaries (all cases), at continuous panel edges parallel to load (Cases 3 & 4), and at all panel edges (Cases 5 & 6) |

Nail Spacing (in.) at diaphragm boundaries (all cases), at continuous panel edges parallel to load (Cases 3 & 4), and at all panel edges (Cases 5 & 6) |

||||||||||||

|

4 |

2-1/2 |

4 |

2-1/2 |

||||||||||

|

Nail Spacing (in.) at other panel edges (Cases 1, 2, 3, & 4) |

Nail Spacing (in.) at other panel edges (Cases 1, 2, 3, & 4) |

||||||||||||

|

6 |

4 |

4 |

3 |

6 |

4 |

4 |

3 |

||||||

|

Structural I |

10d |

1-1/2 |

15/32 |

3 4 4 |

2 2 3 |

605 700 875 |

815 915 1220 |

875 1005 1285 |

1150 1290 1395 |

847 980 1225 |

1140 1280 1707 |

1225 1407 1800 |

1610 1805 1952 |

|

19/32 |

3 4 4 |

2 2 3 |

670 780 965 |

880 990 1320 |

965 1110 1405 |

1255 1440 1790 |

937 1092 1350 |

1232 1385 1847 |

1350 1555 1967 |

1757 2015 2505 |

|||

|

23/32 |

3 4 4 |

2 2 3 |

730 855 1050 |

955 1070 1430 |

1050 1210 1525 |

1365 1565 1800 |

1022 1197 1470 |

1337 1497 2002 |

1470 1695 2135 |

1910 2190 2520 |

|||

|

Sheathing and Single-Floor (DOC PS1 and PS2) |

10d |

1-1/2 |

15/32 |

3 4 4 |

2 2 3 |

525 605 765 |

725 815 1085 |

765 875 1130 |

1010 1105 1195 |

735 847 1070 |

1015 1140 1520 |

1070 1225 1582 |

1415 1547 1672 |

|

19/32 |

3 4 4 |

2 2 3 |

650 755 935 |

860 965 1290 |

935 1080 1365 |

1225 1370 1485 |

910 1057 1310 |

1205 1350 1805 |

1310 1512 1910 |

1715 1917 2080 |

|||

|

23/32 |

3 4 4 |

2 2 3 |

710 825 1020 |

935 1050 1400 |

1020 1175 1480 |

1335 1445 1565 |

995 1155 1427 |

1310 1470 1960 |

1427 1645 2072 |

1870 2022 2190 |

|||

a. See AWC SDPWS for the following: For general construction requirements see 4.2.7. For specific requirements see 4.2.8.1 for wood structural panel diaphragms. See Figure 4C for nailing diagrams. See Appendix A for common nail dimensions.

b. For species and grades of framing other than Douglas-Fir-Larch or Southern Pine, reduced nominal unit shear capacities shall be determined by multiplying the tabulated nominal unit shear capacity by the Specific Gravity Adjustment Factor = [1-(0.5-G)], where G = Specific Gravity of the framing lumber from the NDS (Table 12.3.3A). The Specific Gravity Adjustment Factor shall not be greater than 1.

c. See AWC SDPWS Table 4.2B for Case definitions.

d. See AWC SDPWS Table 4.2B for the apparent shear stiffness values (Ga).

e. Tabulated nominal unit shear capacities are applicable for carbon steel smooth shank nails of the specified type and size.

(Ord. 22-10 § 2, 12/13/22)

18.08.080 Section 2306.3 Is Amended.

Section 2306.3 is amended to read as follows:

2306.3 Wood-frame shear walls. Wood-frame shear walls shall be designed and constructed in accordance with AWC SDPWS. Where Allowable Stress Design is used, Table 2306.3(4) may be applied. Application of Table 4.3A of AWC SDPWS shall include the following:

1. Wood structural panel thickness for shear walls shall not be less than 3/8 inch thick. When 3/8-inch or 7/16-inch thick panels are used, studs shall not be spaced at more than 16 inches on center.

2. The maximum unit shear capacities for 3/8 inch wood structural panels resisting seismic forces shall be 200 pounds per linear foot (plf) using ASD or 280 plf using LRFD.

Exception: Other nominal unit shear capacities may be permitted if such values are substantiated by cyclic testing and approved by the Building Official.

3. Nails shall be placed not less than 1/2 inch in from the panel edges and not less than 3/8 inch from the edge of the connecting members for shear greater than 350 plf using ASD or 490 plf using LRFD. Nails shall be placed not less than 3/8 inch from panel edges and not less than 1/4 inch from the edge of the connecting members for shears of 350 plf or less using ASD or 490 plf or less using LRFD.

2306.3.1 Application of Table 4.3B of AWC SDPWS shall not be permitted.

2306.3.2 See section 2505.4 as amended for provisions regarding gypsum board and portland cement plaster shear walls.

2306.3.3 Shear walls using panels fastened with staples shall not be permitted.

Exception: Allowable shear values where panels are fastened to framing members with staples may be used if such values are substantiated by cyclic testing and approved by the Building Official.

2306.3.4 The allowable shear values in Tables 2306.3(1) and 2306.3(2) are permitted to be increased 40 percent for wind design. Panels complying with ANSI/APA PRP-210 shall be permitted to use design values for Plywood Siding in the AWC SDPWS.

(Ord. 22-10 § 2, 12/13/22)

18.08.090 Section 2307.2 Is Added.

Section 2307.2 is added to read as follows:

2307.2 Wood-frame shear walls. Wood-frame shear walls shall be designed and constructed in accordance with Section 2306.3 as applicable.

(Ord. 22-10 § 2, 12/13/22)

18.08.100 Table 2306.3(4) Is Added.

Table 2306.3(4) is added as follows:

|

Sheathing Material |

Minimum Nominal Panel Thickness (in.) |

Minimum Fastener Penetration into Framing or Blocking (in.) |

Nail Size (common) |

SEISMIC |

WIND |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

Panel Edge Fastener Spacing (in.) |

Panel Edge Fastener Spacing (in.) |

||||||||||

|

6 |

4 |

3 |

2 |

6 |

4 |

3 |

2 |

||||

|

Wood Structural Panels – Structural I |

3/8 7/16 15/32 |

1-3/8 |

8d |

200 255 280 |

200 395* 430* |

200 505* 550* |

200* 670* 730* |

322 357 392 |

505 552 602 |

645 707 770 |

855* 937* 1022* |

|

15/32 |

1-1/2 |

10d |

340 |

510* |

665* |

870* |

475 |

715 |

930* |

1217* |

|

|

Wood Structural Panels – Sheathing (DOC PS 1 or PS 2) |

3/8 |

1-1/4 |

6d |

200 |

200 |

200 |

200* |

280 |

420 |

545 |

715* |

|

3/8 7/16 15/32 |

1-3/8 |

8d |

200 240 260 |

200 350 380* |

200 450* 490* |

200* 585* 640* |

307 335 365 |

447 490 532 |

575 630 685 |

742* 820* 895* |

|

|

15/32 19/32 |

1-1/2 |

10d |

310 340 |

460* 510* |

600* 665* |

770* 870* |

435 475 |

645 715 |

840* 930* |

1077* 1217* |

|

|

Plywood Siding |

3/8 |

1-1/4 1-3/8 |

6d 8d |

140 160 |

200 200 |

200 200 |

200* 200* |

195 225 |

295 335 |

385 435 |

505* 575* |

* Framing members and blocking at adjoining panel edges shall be 3" nominal or greater per AWC SDPWS Section 4.3.7.1, item 5.

a. Where panels are applied on both faces of a wall and nail spacing is less than 6" on center on either side, panel joints shall be offset to fall on different framing members, or framing shall be 3" nominal or thicker at adjoining panel edges and nails at all panel edges shall be staggered.

b. Where the width of framing members is required to be 3” nominal, two 2" nominal members shall be permitted provided they are fastened together to transfer the shear between members.

c. Where 3/8" or 7/16" sheathing is used, studs shall not be spaced more than 16" on center. Otherwise, studs shall not be spaced at more than 24" on center.

d. Where studs are spaced at 24" on center, nailing to intermediate framing shall be spaced at 6” on center maximum. Where studs are spaced less than 24" on center, nailing to intermediate framing shall be spaced at 12" on center maximum.

e. Steel plate washers shall be provided at foundation anchor bolts as required by AWC SDPWS Section 4.3.6.4.3. When required, plate washers shall not be less than 0.229"x3"x3" in size. The hole in the plate washer shall be permitted to be diagonally slotted with a width of up to 3/16" larger than the bolt diameter and a slot length not to exceed 1-3/4", provided a standard cut washer is placed between the plate washer and the nut.

f. Allowable shear values for 7/16" sheathing are permitted to be increased to values shown for 15/32” sheathing with the same nailing provided panels are applied with long dimension across studs.

g. Galvanized nails shall be hot dipped or mechanically deposited.

h. Nails shall be placed not less than 1/2" in from panel edges and not less than 3/8” from the edge of the connecting members for shears greater than 350 plf. Nails shall not be placed not less than 3/8" from panel edges and not less than 1/4" from the edge of the connecting members for shears of 350 plf or less.

i. See AWC SDPWS for the following: For general construction requirements see 4.3.6. For specific requirements for wood structural panel shearwalls see 4.3.7.1. For shear wall aspect ratios and capacity adjustments see 4.3.3. For the apparent shear stiffness values (Ga), see Table 4.3A. See Appendix A for common nail dimensions.

j. For species and grades of framing other than Douglas-Fir-Larch or Southern Pine, reduced nominal unit shear capacities shall be determined by multiplying the tabulated nominal unit shear capacity by the Specific Gravity Adjustment Factor = [1-(0.5-G)], where G = Specific Gravity of the framing lumber from the NDS (Table 12.3.3A). The Specific Gravity Adjustment Factor shall not be greater than 1.

k. See AWC SDPWS Table 4.3A for additional notes.

18.08.110 Table 2308.6.1 Is Amended.

Table 2308.6.1 is amended as follows:

(Ord. 22-10 § 2, 12/13/22)

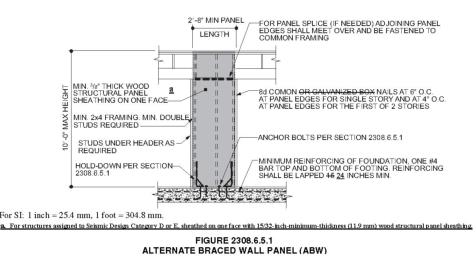

18.08.120 Section 2308.6.5 Is Amended.

Section 2308.6.5 is amended as follows:

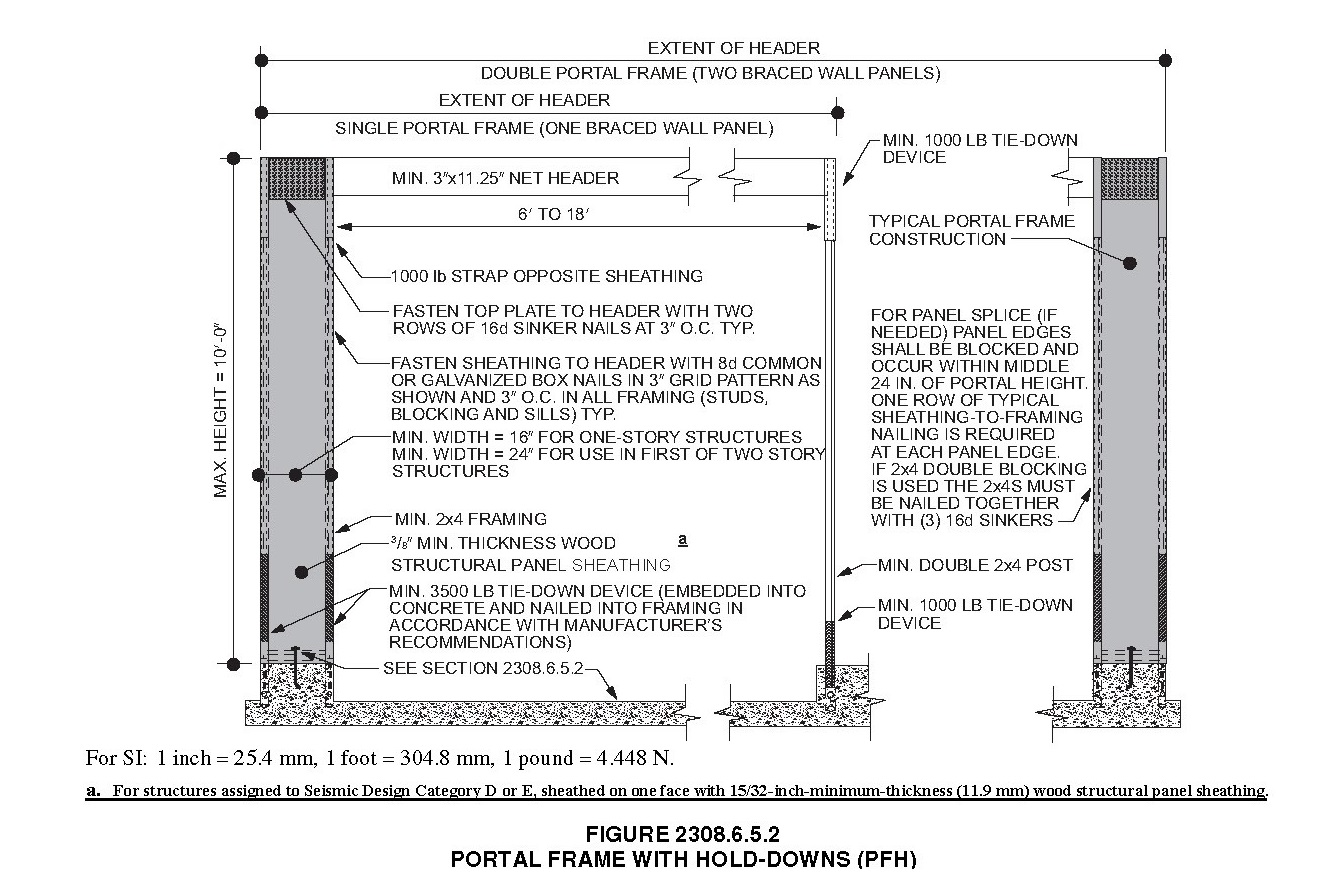

2308.6.5 Alternative bracing. An alternate braced wall (ABW) or a portal frame with hold- downs (PFH) described in this section is permitted to substitute for a 48-inch (1219 mm) braced wall panel of Method DWB, WSP, SFB, PBS, PCP or HPS. For Method GB, each 96-inch (2438 mm) section (applied to one face) or 48-inch (1219 mm) section (applied to both faces) or portion thereof required by Table 2308.6.1 is permitted to be replaced by one panel constructed in accordance with Method ABW or PFH.

2308.6.5.1 Alternate braced wall (ABW). An ABW shall be constructed in accordance with this section and Figure 2308.6.5.1. In one-story buildings, each panel shall have a length of not less than 2 feet 8 inches (813 mm) and a height of not more than 10 feet (3048 mm). Each panel shall be sheathed on one face with 3/8-inch (3.2 mm) minimum-thickness wood structural panel sheathing nailed with 8d common nails in accordance with Table 2304.10.2 and blocked at wood structural panel edges. For structures assigned to Seismic Design Category D or E, each panel shall be sheathed on one face with 15/32-inch-minimum-thickness (11.9 mm) wood structural panel sheathing nailed with 8d common nails spaced 3 inches on panel edges, 3 inches at intermediate supports. Two anchor bolts installed in accordance with Section 2308.3.1 shall be provided in each panel. Anchor bolts shall be placed at each panel outside quarter points. Each panel end stud shall have a hold-down device fastened to the foundation, capable of providing an approved uplift capacity of not less than 1,800 pounds (8006 N). The hold-down device shall be installed in accordance with the manufacturer’s recommendations. The ABW shall be supported directly on a foundation or on floor framing supported directly on a foundation that is continuous across the entire length of the braced wall line. This foundation shall be reinforced with not less than one No. 4 bar top and bottom. Where the continuous foundation is required to have a depth greater than 12 inches (305 mm), a minimum 12-inch by 12-inch (305 mm by 305 mm) continuous footing or turned-down slab edge is permitted at door openings in the braced wall line. This continuous footing or turned-down slab edge shall be reinforced with not less than one No. 4 bar top and bottom. This reinforcement shall be lapped 24 inches (610 mm) with the reinforcement required in the continuous foundation located directly under the braced wall line.

Where the ABW is installed at the first story of two-story buildings, the wood structural panel sheathing shall be provided on both faces, three anchor bolts shall be placed at one-quarter points and tie-down device uplift capacity shall be not less than 3,000 pounds (13 344 N).

2308.6.5.2 Portal frame with hold-downs (PFH). A PFH shall be constructed in accordance with this section and Figure 2308.6.5.2. The adjacent door or window opening shall have a full-length header.

In one-story buildings, each panel shall have a length of not less than 16 inches (406 mm) and a height of not more than 10 feet (3048 mm). Each panel shall be sheathed on one face with a single layer of 3/8-inch (9.5 mm) minimum-thickness wood structural panel sheathing nailed with 8d common nails in accordance with Figure 2308.6.5.2. For structures assigned to Seismic Design Category D or E, each panel shall be sheathed on one face with 15/32-inch-minimum-thickness (11.9 mm) wood structural panel sheathing nailed with 8d common nails spaced 3 inches on panel edges, 3 inches at intermediate supports and in accordance with Figure 2308.6.5.2. The wood structural panel sheathing shall extend up over the solid sawn or glued-laminated header and shall be nailed in accordance with Figure 2308.6.5.2. A built-up header consisting of at least two 2-inch by 12-inch (51 mm by 305 mm) boards, fastened in accordance with Item 24 of Table 2304.10.2 shall be permitted to be used. A spacer, if used, shall be placed on the side of the built-up beam opposite the wood structural panel sheathing. The header shall extend between the inside faces of the first full-length outer studs of each panel. The clear span of the header between the inner studs of each panel shall be not less than 6 feet (1829 mm) and not more than 18 feet (5486 mm) in length. A strap with an uplift capacity of not less than 1,000 pounds (4,400 N) shall fasten the header to the inner studs opposite the sheathing. One anchor bolt not less than 5/8 inch (15.9 mm) diameter and installed in accordance with Section 2308.3.1 shall be provided in the center of each sill plate. The studs at each end of the panel shall have a hold-down device fastened to the foundation with an uplift capacity of not less than 3,500 pounds (15 570 N).

Where a panel is located on one side of the opening, the header shall extend between the inside face of the first full-length stud of the panel and the bearing studs at the other end of the opening. A strap with an uplift capacity of not less than 1,000 pounds (4400 N) shall fasten the header to the bearing studs. The bearing studs shall also have a hold-down device fastened to the foundation with an uplift capacity of not less than 1,000 pounds (4400 N). The hold-down devices shall be an embedded strap type, installed in accordance with the manufacturer’s recommendations. The PFH panels shall be supported directly on a foundation that is continuous across the entire length of the braced wall line. This foundation shall be reinforced with not less than one No. 4 bar top and bottom. Where the continuous foundation is required to have a depth greater than 12 inches (305 mm), a minimum 12-inch by 12-inch (305 mm by 305 mm) continuous footing or turned-down slab edge is permitted at door openings in the braced wall line. This continuous footing or turned-down slab edge shall be reinforced with not less than one No. 4 bar top and bottom. This reinforcement shall be lapped not less than 24 inches (610 mm) with the reinforcement required in the continuous foundation located directly under the braced wall line.

Where a PFH is installed at the first story of two-story buildings, each panel shall have a length of not less than 24 inches (610 mm).

(Ord. 22-10 § 2, 12/13/22)

18.08.130 Section 2308.6.8.1 Is Amended.

Section 2308.6.8.1 is amended to read as follows:

2308.6.8.1 Foundation requirements. Braced wall lines shall be supported by continuous foundations. Exterior braced wall panels shall be in the same plane vertically with the foundation or the portion of the structure containing the offset shall be designed in accordance with accepted engineering practice and Section 2308.1.1.

(Ord. 22-10 § 2, 12/13/22)

18.08.140 Section 2308.6.9 Is Amended.

Section 2308.6.9 is amended to read as follows:

2308.6.9 Attachment of sheathing. Fastening of braced wall panel sheathing shall not be less than that prescribed in Table 2308.6.1 or 2304.10.2. Wall sheathing shall not be attached to framing members by adhesives. Staple fasteners in Table 2304.10.2 shall not be used to resist or transfer seismic forces in structures assigned to Seismic Design Category D, E or F.

Exception: Staples may be used to resist or transfer seismic forces when the allowable shear values are substantiated by cyclic testing and approved by the building official.

All braced wall panels shall extend to the roof sheathing and shall be attached to parallel roof rafters or blocking above with framing clips (18 gauge minimum) spaced at maximum 24 inches (6096 mm) on center with four 8d nails per leg (total eight 8d nails per clip). Braced wall panels shall be laterally braced at each top corner and at maximum 24 inches (6096 mm) intervals along the top plate of discontinuous vertical framing.

(Ord. 22-10 § 2, 12/13/22)